Whento choose the right finish for the surface. At AMX Printing, we offer a wide range of cover options to enhance the appearance and durability of your printed materials it comes to printing, the product surface is often the first thing that catches the eye. It serves as a visual representation of the content outside and inside, making it crucial .

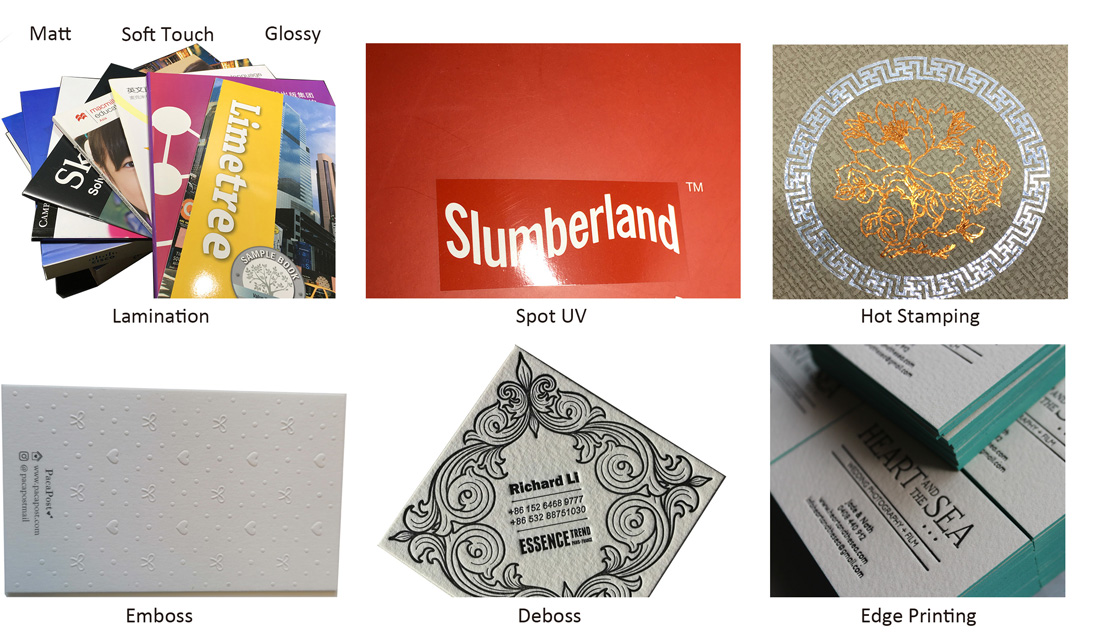

Lamination

One of the most popular surface finishes is lamination. It involves applying a thin layer of plastic film to the surface of the product, providing protection against moisture, tearing, and general wear and tear. Lamination also adds a glossy or matte finish, depending on your preference.

Glossy Lamination

Glossy lamination gives the cover a shiny and reflective appearance. It enhances the colors and patterns on the cover, making them more vibrant and eye-catching. This finish is particularly suitable for designs with bright colors and high-resolution images. Additionally, glossy lamination adds a layer of protection, making the cover more resistant to scratches and fading.

Matte Lamination

If you prefer a more subdued and elegant look, matte lamination is an excellent choice. It gives the product surface a smooth and non-reflective finish, reducing glare and fingerprints. Matte lamination works well for designs with a minimalist aesthetic or for materials that require a more professional and sophisticated appearance. Like glossy lamination, it also provides durability and protection.

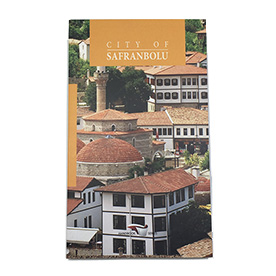

Hot Stamping

For a touch of luxury and sophistication, hot stamping is a good option that stands out. It involves applying a metallic or pigmented foil to the product surface using heat and pressure. This process creates a shiny and eye-catching design or text on the surface, enhancing its visual appeal.

Hot stamping can be used to add text, logos, or decorative elements to the product surface. It is commonly used for labels, boxes, bags, cards, invitations, books and brochures. The metallic shine of hot stamping instantly grabs attention and adds a touch of elegance and prestige to your printed materials. Whether you want to create a bold and striking design or add subtle accents, hot stamping is an excellent choice for enhancing the visual appeal of your products. For more foil colors, pls check Hot Stamping Colors.

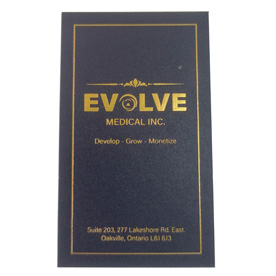

Spot UV

Spot UV is a technique that involves applying a glossy, clear coating to specific areas of the cover, creating a contrast with the rest of the surface. It adds depth and dimension to the design, making certain elements stand out. Chinaprinting4u offers precise and high-quality spot UV printing, allowing you to highlight logos, text, or images on your cover.

Spot UV is commonly used for business cards, book covers, and marketing materials. By applying spot UV to select areas, you can create a visually striking effect that captures attention and adds a touch of sophistication. Whether you want to make your logo pop or draw attention to important information, spot UV is a versatile option that can elevate the overall look of your cover.

UV Varnish

UV Varnish, also mean uv oil coating, is a transparent coating that adds a subtle shine and protection to the interior page or package. It is applied to the entire or spot area, enhancing the colors and making them more vibrant. UV varnish also provides resistance against fingerprints, smudges, and minor scratches. It is suitable for a wide range of printed materials, from book to package, and adds a polished and professional look.

Whether you want a glossy, matte or spot finish, varnish is an excellent choice for adding durability and enhancing the overall look of your interior page.

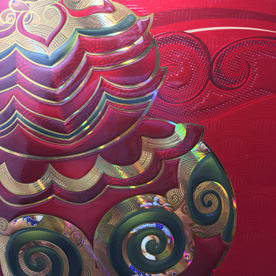

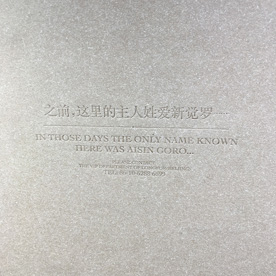

Emboss

Embossing is a great option that creates a raised or three-dimensional effect on the surface. It involves pressing the surface against a metal die, which transfers the design onto the material. Embossing adds texture and depth to the cover, making it visually appealing and tactile. This technique is often used for logos, titles, or important elements that need to stand out.

Embossing is often used for book covers, business cards, journals, invitations, luxury labels, boxes and gift bags. It adds a sophisticated and luxurious touch to your printed materials, making them stand out from the competition. Whether you want to create an elegant logo or add intricate details to your design, embossing is a versatile option that can elevate the overall look and feel of your cover.

Deboss

Debossing is the opposite of embossing, as it creates a depressed or indented effect on the paper. It adds a subtle and sophisticated touch to the design, giving it a unique and tactile appearance. Debossing works well for minimalist and elegant designs, adding a sense of depth and luxury.

Debossing is often used for luxury packaging, business cards, and notebooks. It adds a subtle and sophisticated touch to the produce surface, making it visually appealing and memorable. Whether you want to create a minimalist logo or add texture to your design, debossing is a versatile option that can enhance the overall look and feel of your printed materials.

Die Cut

Usually the die-cutting process is a technology that combines the die-cutting knife and the crimping knife in the same template to hollow out the shape of the material. Root die cutting allows various printed packaging to be presented in three-dimensional and curved shapes, and the various shapes and shapes created are more beautiful, refined and full of creativity. Die cutting is a cover option that involves cutting the cover into a specific shape or pattern. It allows for creative and unique designs, making your printed materials stand out from the crowd.

Die cutting is often used for labels, boxes, bags, business cards, invitations, pop-up books, and packaging to create memorable and visually appealing covers.

Crystal Raised Letters

Crystal raised lettering is a premium printing technique that creates a glossy, transparent 3D effect on business cards and swing tags. The letters appear elevated and glass-like, catching light brilliantly. This elegant finish adds sophistication and tactile appeal, making printed materials stand out through both visual and physical dimensions.

If you need velevet lamination or other crafts not list as above, pls contact elina@amxprinting.com, we can custom velvet lamiantion at 1000SQ.meters and custom paper patterns at 3000pcs/design.